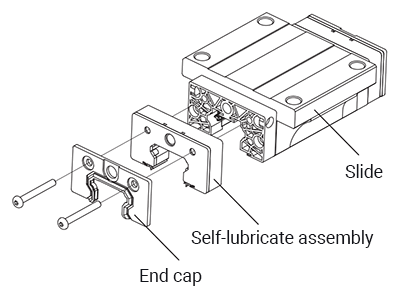

Self-Lubricate Assembly (LS)

Self-lubricate assembly (LS) automatically spreads the lubrication oil to form the oil film all over the rail rolling surface to lubricate the rolling elements appropriately. Different from conventional lubrication loop that delivers lubrication oil to the rolling elements, the combination of lubrication loop and self-lubricate assembly (LS) provides more reliable lubrication.

Be sure to assemble the self-lubricate assembly (LS) cap outward to use the fitting correctly.

Use lubrication oil of viscosity 100〜400 to ensure the expected lubrication effect.

If pressure lubrication is used simultaneously, reduce the pressure lubrication adequately.

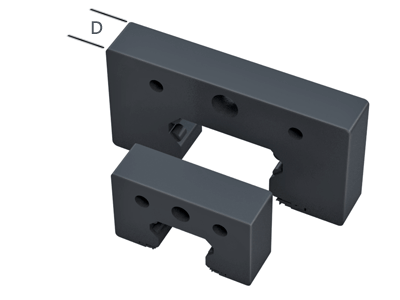

Specification of Self-Lubricate Assembly

| Specification | D (mm) Thickness of single self-lubricate assemble | V (cm³) Volume of oil lubrication |

|---|---|---|

| 15 Type | 10.3 | 2.0 |

| 20 Type | 10.3 | 2.5 |

| 25 Type | 10.3 | 3.0 |

| 30 Type | 10.3 | 5.5 |

| 35 Type | 10.7 | 8.5 |

| 45 Type | 13.0 | 15.0 |

| 55 Type | 13.0 | 22.5 |

| Code | End Seal | Bottom Seal | Top Seal | Double Seal | Scraper | Self-lubricate components (LS) |

|---|---|---|---|---|---|---|

| AA | ||||||

| UA | ||||||

| SA | ||||||

| DA | ||||||

| ZA | ||||||

| KA | ||||||

| EA | ||||||

| FA | ||||||

| GA |

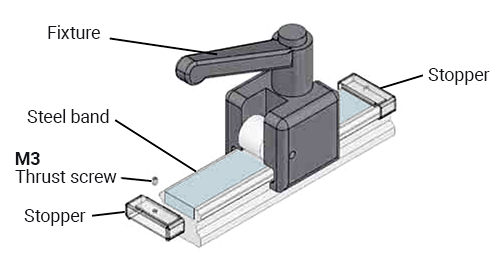

Steel Band Assembly

Steel band covers the rail to prevent the slide from being damaged by the dust captured by the height difference between the hole cap and the rail. The steel band consists the components as in the figure below.

Steel Band Specifications

| Specifications | Width | Thickness |

|---|---|---|

| 15 Type | 10 mm | 0.3 mm (including adhesive) |

| 20 Type | 11 mm | 0.3 mm (including adhesive) |

| 25 Type | 13 mm | 0.3 mm (including adhesive) |

| 30 Type | 16 mm | 0.3 mm (including adhesive) |

| 35 Type | 18 mm | 0.3 mm (including adhesive) |

| 45 Type | 27 mm | 0.3 mm (including adhesive) |

| 55 Type | 29 mm | 0.3 mm (including adhesive) |

Steel Band Compositions

1. Steel band box : All steel band are packed in with the same box, but each type steel band varies in size and so are secured by paper stuff.

2. Steel band fixture : To secure the steel band accurately in the centre of the rail.

3. Stopper : To secure the steel bands extensions at both ends of the rail from falling off.

Cautions

Before attaching the steel band, clean up the rail surface thoroughly with detergent, and be sure there is no more oil left on the rail.

1. Be sure there is no more stains and contamination before attaching the steel band.

2. Use steel band only in temperature 20~40°C, or the effect is not guaranteed.

3. Keep hands off the adhesive to assure the best attaching result

4. Shelf life of steel band is 6 month.